A photovoltaic panel contains various materials, most of them non-hazardous, such as glass, plastics and aluminium. It is not difficult to understand that the proper recycling of photovoltaic panels could become a rich resource for the production of materials to be reused in the manufacture of new panels and beyond. This requires the dismantiling of the panel and the correct separation of its constituent materials. The development of a market for end-of-life solar panels would also be an interesting opportunity to explore, especially in developing countries where purchasing power is limited. Recycling photovoltaic panels and recovering the materials they are made of is essential. We could say there is indeed a small mine inside. Cooper, silver, aluminium, glass and crystalline silicon are the most valuable materials.

From a typical photovoltaic panel weighing around 22kg of varoius metals, 1.7 kg of plastics, 2.8 kg of silicon, 2.9 kg of aluminium and 13.8 kg of glass.

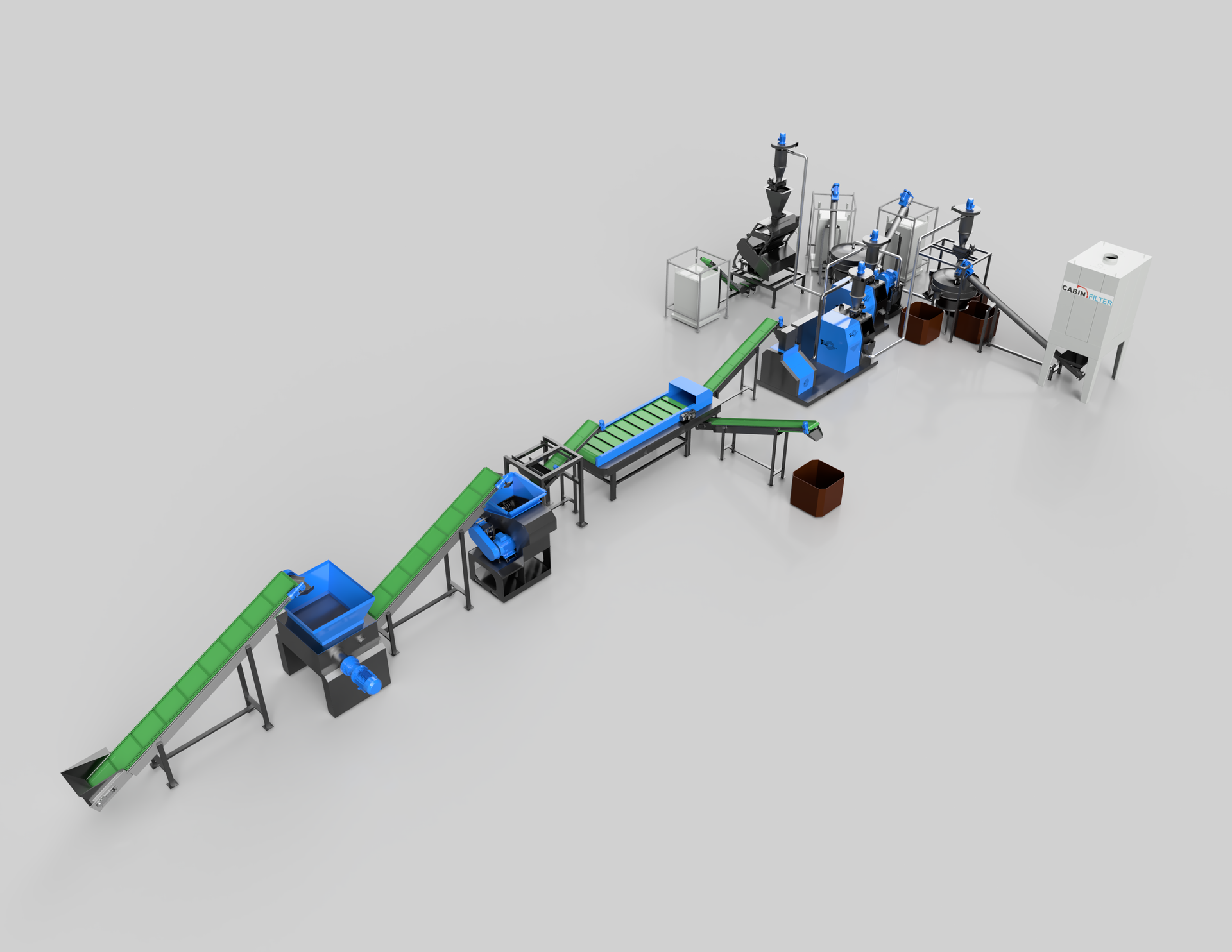

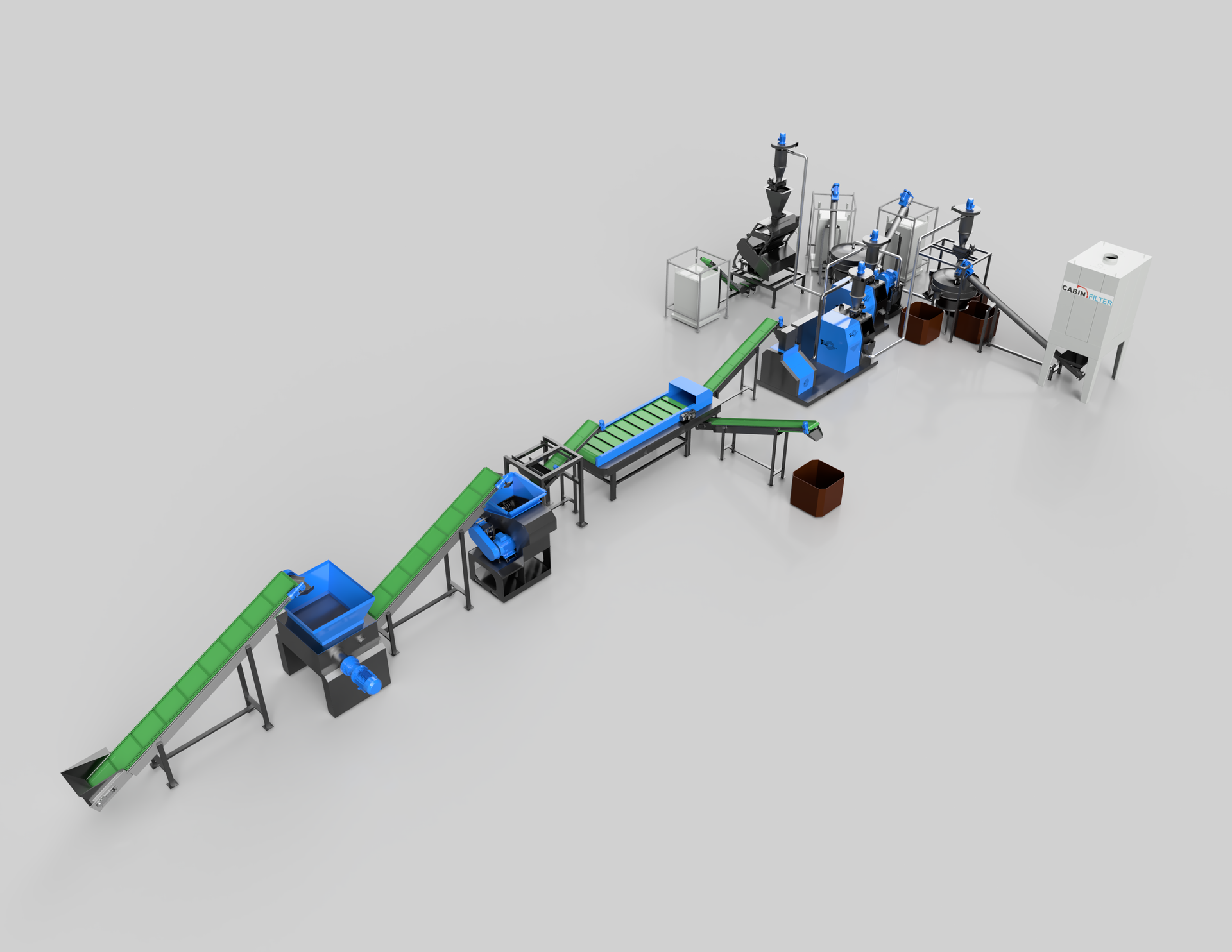

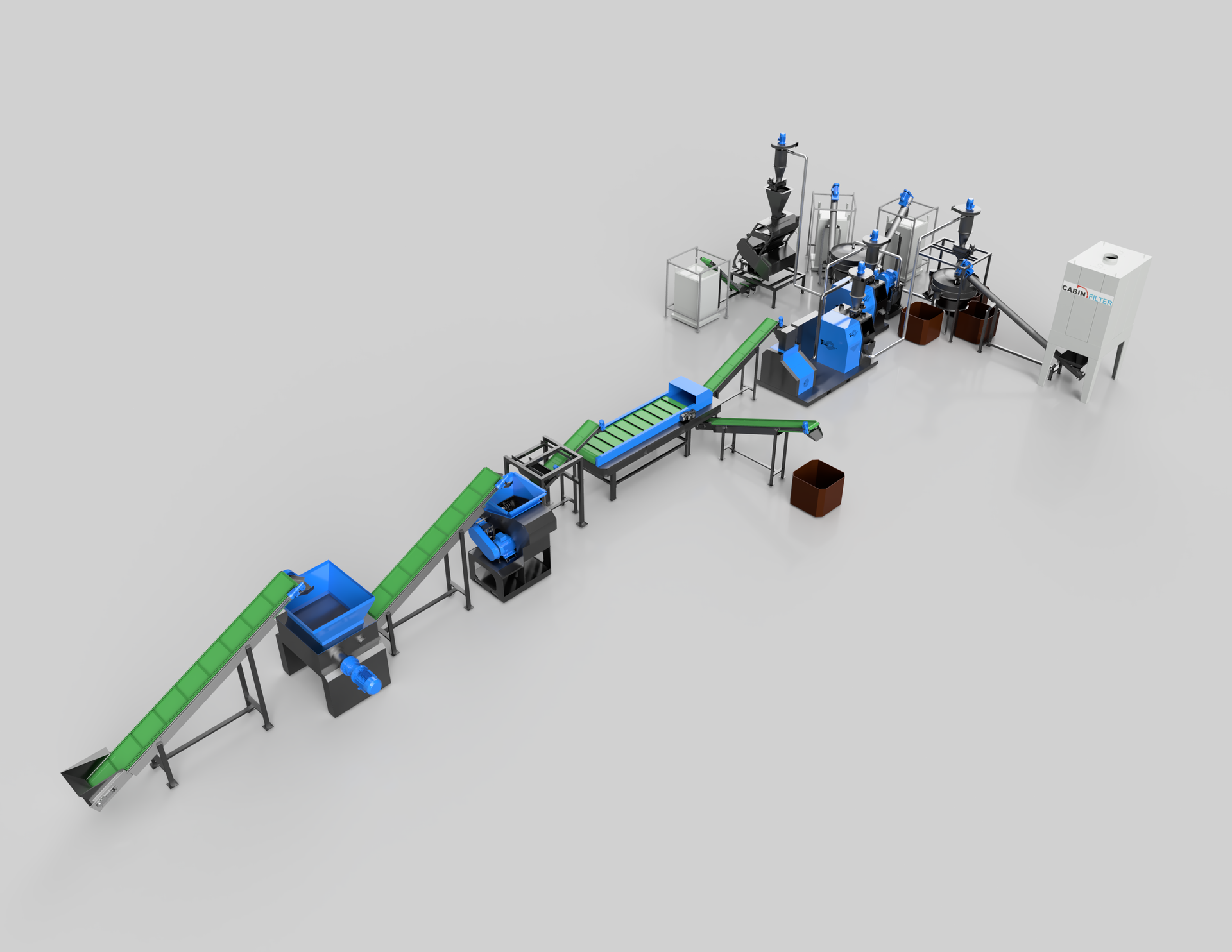

However, the mechanical process for the most common panel types begins with removal of the aluminium frame, the connecting cables and the junctions box.

The layer of glass, plastics and solar cells is then precessed in a machine that scrapes off the glass. The remaining layer is then shredde and passed through a much finer sieve, which separates the PET and EVA plastics, silicon powder and cooper connectors.